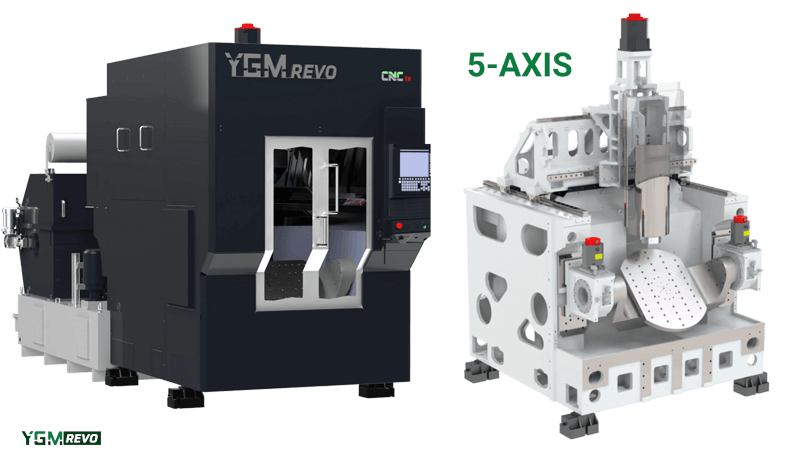

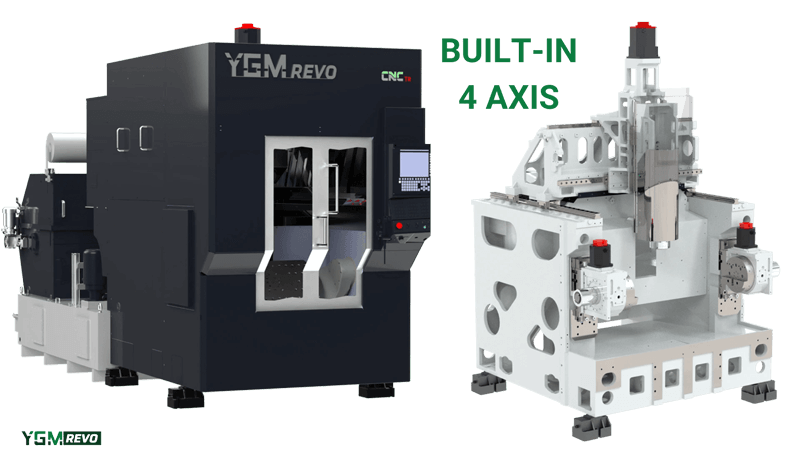

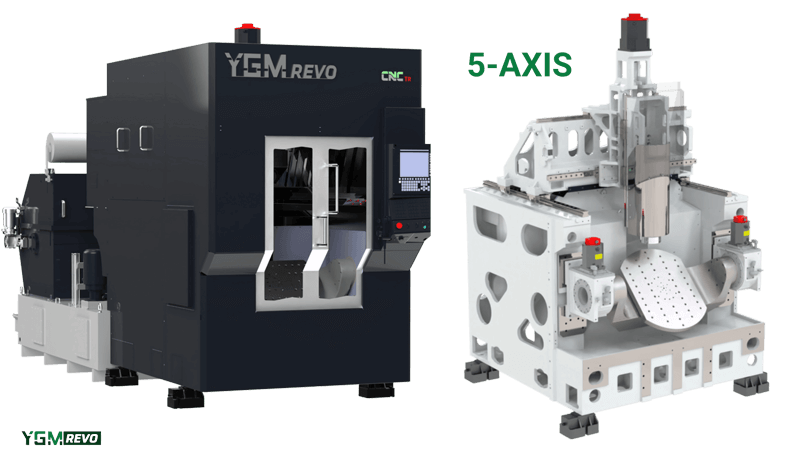

SİSTEM KURULUMU

YGM REVO

Yerli ve Ulusal Üretim YGM REVO 5 Eksenli, 4 Eksenli, 3 Eksenli ve Otomatik Palet Değiştiricili CNC Makineleri.

Ayrıca, yıl sonuna kadar bir dönüş seçeneği eklenecektir.

TECHNICAL DETAILS

XYZ EKSEN HAREKETLERİ: 700 X 500 X 400 mm

Maksimum Hız: 16.000 RPM

Güç: 18.5 kW

Tork: 80.3 N.m

Arayüz: HSK-A63

Rapid Traverse: 50m/min

Cutting Feedrate: 25m/min

X/Y/Z: 1.6G/1.4G/2.0G

Positioning –

Without Scale / With Scale:±0.0040 /±0.0025 mm

Repeatability –

Without Scale / With Scale: ±0.0020 /±0.0015 mm

Takım Depolama Kapasitesi: 33

Maksimum Takım Çapı

(bitişik aletlerle / bitişik aletler olmadan): 80 / 140 mm

Maksimum Alet Uzunluğu: 320 MM

Maksimum Alet Ağırlığı: 8kg (sınırlama ile)

Talaştan Talaşa: 2,8 saniye

STANDART ÖZELLİKLER

- Çift Sargılı İş Mili

- İş Mili Su Soğutma

- Harici Yan Takım Yükleme İstasyonu

- Çok Fonksiyonlu Talaş Konveyörü (Tambur, Kazıyıcı ve Menteşe)

- 600 L Soğutma Sıvısı Deposu

- İş Milinden Geçen Soğutma Sıvısı

- (70 Bar Yüksek Basınçlı Pompa)

- İş Mili Nozul Soğutma Sıvısı (6 Nozul)

- Programlanabilir Taban Nozul Soğutma Sıvısı

- Programlanabilir İç Hazne Nozul Soğutma Sıvısı

- Hidrostatik Kağıt Filtre

- Yağ Süzgeci

- Soğutma Sıvısı Düşük/Yüksek Seviye Sensörü

- İş Parçası Yıkama Tabancası

- Hava Tabancası

- Talaş Arabası

- Hidrolik Fikstür Kontrolü Ana Ekrandan Çalıştırılır

- Hidrolik Fikstür Hazırlığı

**9 ek bağlantı noktası için 9 manifold dahildir.

*Valfler, Hava Koltuk Kontroller, Borular vb. dahil değildir. - Auto Centralize Grease Lubrication

- Servo Autodoor

- Tool Lenght Measurement Include Broken Tool Sensor

- Otomatik Merkezileştirilmiş Gres Yağlama

- Servo Otomatik Kapı

- Takım Uzunluğu Ölçümü Kırık Takım Sensörü Dahil

- Otomatik İş Parçası Ölçümü

- Robot Arayüzü

- Elektrik Kabini Fan Soğutucu

- Fanuc 0i-MF Plus Kontrolör

- Kompakt Flash Kart, 2 GB

(Veri Yedekleme veya Veri Sunucusu) - Taşınabilir Manuel Darbe Jeneratörü

- AICC II (200 Ön İzleme)

- 8000 rpm Sert Kılavuz Çekme

- 10,4″ Renkli LCD Ekran

- İş Mili Yük Monitörü

- Takım Ömrü Monitörü

- CE Yönetmeliği

Doğrusal Ölçek Geri Besleme / X – Y – Z Ekseni

Ek Hidrolik Valf

Sis Toplayıcı

Elektrik Dolabı Klima